1. Introduction: The Problem Faced by Australian Industries

Australia’s industrial landscape—from mining and energy to marine and food processing—faces an ongoing challenge: extreme temperatures and corrosive environments that degrade structural materials over time. Standard stainless steels often fail in such high-temperature settings, leading to equipment failures, unplanned downtime, and rising maintenance costs.

This has created a strong demand for heat-resistant, durable, and corrosion-resistant materials that can operate seamlessly in the most demanding environments. That’s where Stainless Steel 310 Sheets come in.

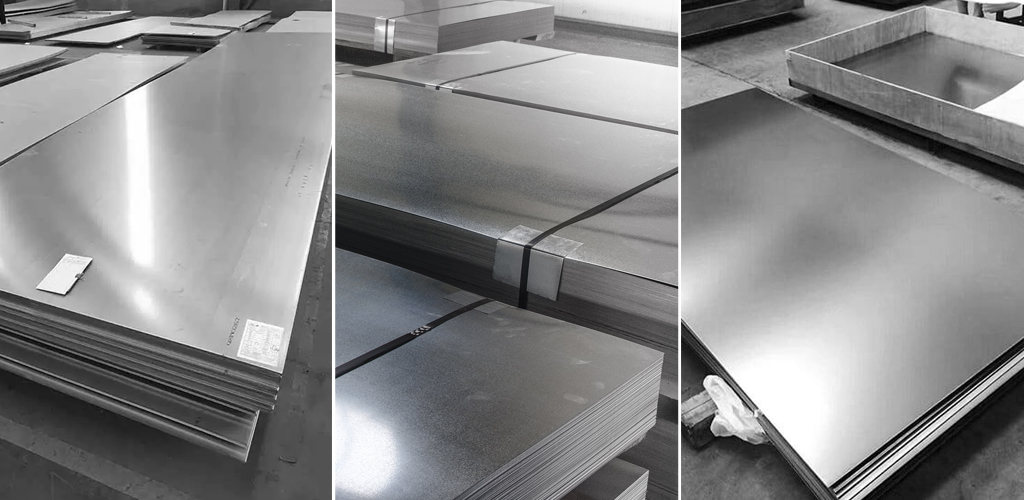

2. Product Introduction: What Are Stainless Steel 310 Sheets?

Stainless Steel 310 Sheets are austenitic stainless steel sheets containing high levels of chromium (25%) and nickel (20%). This unique composition makes them highly resistant to oxidation and corrosion, even at temperatures as high as 1100°C.

These sheets conform to global standards such as:

ASTM A240 / ASME SA240

UNS S31000 / S31008

DIN 1.4841 / 1.4845

Available through trusted Stainless Steel 310 Sheets Suppliers and Stainless Steel 310 Sheets Stockists across Australia, these sheets are a reliable option for industries needing material strength under pressure.

3. Key Advantages of Stainless Steel 310 Sheets

✅ Exceptional Heat Resistance: Performs well at elevated temperatures without scaling.

✅ Corrosion Resistance: Resists oxidation and atmospheric corrosion in industrial settings.

✅ High Mechanical Strength: Maintains tensile strength even under thermal stress.

✅ Weldability and Fabrication: Easy to weld and fabricate, saving time and effort on-site.

✅ Longer Service Life: Reduces the need for frequent replacements or maintenance.

4. Real-Life Uses in Australia

???? Mining & Metallurgy: Used in heat exchangers, furnace parts, and refining equipment.

⚙️ Petrochemical Industry: Ideal for radiant tubes, combustion chambers, and fluid catalytic crackers.

???? Food Processing Units: Applied in ovens and food-grade machinery for hygienic and high-temp performance.

???? Marine Environments: Perfect for saltwater applications due to high corrosion resistance.

???? Power Plants: Utilized in boiler tubes, headers, and flue gas desulfurization units.

5. Problem Solving and Outcome

By integrating Stainless Steel 310 Sheets, industries have significantly improved equipment lifespan and operational efficiency. The heat resistance and low maintenance requirements result in reduced operational costs and fewer shutdowns.

In Australian mining and oil refining sectors, companies have reported improved thermal efficiency and increased uptime after replacing traditional materials with 310-grade sheets—highlighting the effectiveness of this alloy in the toughest conditions.

6. Conclusion

For industries in Australia battling high temperatures, corrosion, and mechanical stress, Stainless Steel 310 Sheets offer a proven and cost-effective solution. With recognized standards like ASTM A240 / ASME SA240 and availability through leading Stainless Steel 310 Sheets Suppliers and Stockists, these sheets are a smart investment in durability and performance.

Whether you're upgrading industrial furnaces or designing high-temperature equipment, consider SS 310 as your go-to material for peace of mind and long-term results.